Behaviour of 2020 Fuels

The transition from burning high sulphur fuels to low sulphur fuels went more smoothly than even the most optimistic engineer dared to predict.

The industry experienced basically no claims in late 2019 & early 2020. Only a few discussions on the reproducibility and repeatability of the sulphur limit as many fuels were blended very close to or spot on the limit. Blending spot on is, in theory, the best solution for suppliers. But in reality, most fuels are blended on the lower side, suggesting that many suppliers are cautious about going over the limit.

Stability problems

In Q1 we saw some issues with stability. There were apparently fuels in the market which were blended close to the limit of stability. If stability is defined by TSP/TSA =/< 0,1% they were stable at delivery, but not much longer than that. Typically for those fuels were relative high TSP/TSA (>0,05%) and cleanliness tested to 3 or above. We believe those products were a result of an extraordinary and non-foreseen high demand of VLSFO’s, which caused some blenders to compromise on the paraffinic/aromatic ratio.

New challenges

Some fuels revealed a new phenomenon with TSP testing higher than TSA. These fuels had TSA on spec, but TSP was much higher than ISO specified (0,1%). Those fuels are actually on spec, as TSP does not have to be tested, if TSA is within the limit of 0,1%. This phenomenon might create situations where doubtful suppliers could reject claims on technicalities, even if the products were impossible or close to impossible to handle onboard the ships.

Fortunately, those fuels seem to have disappeared and we once again experience very few quality claims. We are also experiencing hardly any compatibility issues, maybe even fewer than pre 2020, which indicates that the very paraffinic products are absent in the marked.

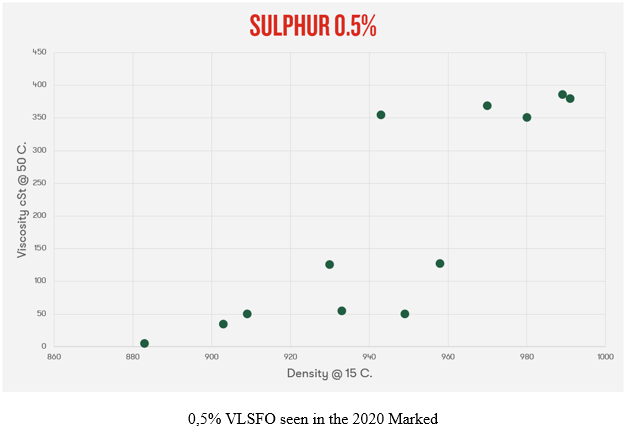

Varying viscosities

As predicted, the VLSFO’s present in the market are of very different quality. All complying with ISO 8217 and 0,5% sulphur but scattered from RMA to RMK residual quality. This means that the viscosity also varies a lot. However, we do not see VLSFO viscosities in the neighbourhood of gas oils lower limits of 2,5 cSt@40C – Be aware that VLSFO’s are defined with a viscosity measured @50C. and Gas Oils @40C.

We frequently get questions on viscosity and requirements for a minimum viscosity, and we have tried to understand why this is important for some owners. One owners answer: it was in relation to a vessel which had a non-working dumping condenser, causing them to use the fuel storage and system to control their surplus steam production. This is a valid point, but in general low viscosity products should not be of less quality than the higher viscosities. Of course, the density should be correspondingly low to fulfil the CCAI number (CCAI is the relation between viscosity and density.)

If a vessel was able to handle and burn RMG380 in 2019, it will most likely also be able to do so this year. Thus, we recommend ordering accordingly. E.g. ISO 8217 2017 edition RMG380 with max sulphur content of 0,5% (or 0,1% for ECA trade).

Please do not hesitate to contact us to get more comprehensive details and guidance for any of your fuel purchases.

Related insights

Aalborg, Press release

European Bunker Markets in 25/26: Consolidation, Capacity, and Change

2025 in Review: Strengthening the Platform

West Africa, Press release

Building Market Share in 2025, Positioning for Sustainable Growth in 2026

A Bunker One Africa Perspective

Houston, Press release

U.S. Bunker Demand in 2025–2026: Why the Gulf Coast Still Leads

A Bunker One Houston Perspective

Aalborg, Press release

Belgium Hit Pause and Maritime Exemptions Remain in Germany

Europe’s implementation of RED III is about to reshape the marine fuel market, but not in a uniform way.